The global bleached kraft pulp market size is projected to grow at a CAGR of 5% over the forecast period of 2024-2032. As industries increasingly shift towards more sustainable production processes and eco-friendly materials, bleached kraft pulp — a high-quality, versatile paper pulp used in various paper products — has become essential in meeting the demands for durable, recyclable, and biodegradable paper. This growth trajectory is driven by the expanding need for packaging, tissue, and specialty papers across a range of sectors, including e-commerce, consumer goods, and printing.

In this blog post, we will explore the key market drivers, challenges, trends, and forecasts that are shaping the global bleached kraft pulp market. We’ll also look at how different applications and regions are influencing market dynamics, and the competitive landscape that is driving innovation and growth within the industry.

Market Overview: Growth Driven by Sustainability and Paper Demand

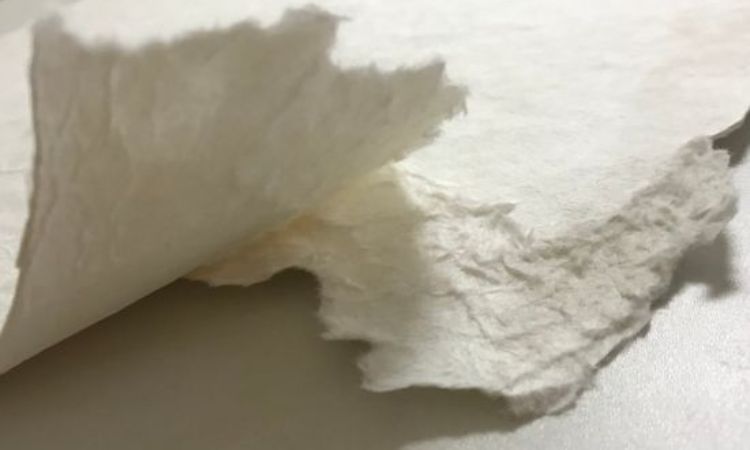

The global bleached kraft pulp market has witnessed significant growth over the past few years, spurred by increasing consumer demand for eco-friendly products and the need for high-quality, sustainable paper solutions. Bleached kraft pulp is primarily derived from wood, and its uses span a wide range of paper products, including packaging, tissue, and graphic papers. It is produced through a chemical process that involves treating wood chips with sodium hydroxide and sodium sulfide, followed by a bleaching process that enhances its quality, brightness, and durability.

Several key factors are driving growth in this market:

-

Rising Demand for Sustainable Packaging: With more companies moving towards environmentally conscious packaging, bleached kraft pulp has become a preferred material due to its recyclability and biodegradability.

-

Increased Paper Consumption Globally: As developing economies continue to urbanize and industrialize, the demand for paper products — including tissue paper, packaging materials, and graphic paper — is surging. This growth is especially prominent in regions like Asia-Pacific and Latin America.

-

Environmental Regulations: Governments around the world are enacting stricter environmental regulations, encouraging industries to adopt sustainable practices, including the use of bleached kraft pulp. Additionally, consumers’ growing preference for eco-friendly products is driving manufacturers to use materials that meet sustainability standards.

-

Technological Advancements: Innovation in pulping and bleaching technologies has led to more efficient and environmentally friendly production processes, which has further enhanced the appeal of bleached kraft pulp.

Market Segmentation: By Process, Product, and Application

The bleached kraft pulp market can be segmented by process type, product type, and application. Understanding these segments is key to analyzing the broader market trends and forecasting future demand.

By Process

Bleached kraft pulp is produced using various processes, each contributing different qualities to the final product. The primary processes used are:

-

Mechanical Process: In this process, wood fibers are ground down to create a pulp, which is then bleached. This method is commonly used for producing lower-quality pulp, although advances in technology have improved its efficiency and sustainability. Mechanical pulps are typically used for newsprint and lower-end paper products.

-

Chemical Process (Kraft Pulping): The chemical pulping process involves treating wood chips with chemicals, particularly sodium hydroxide and sodium sulfide, which break down lignin and other non-fibrous materials. This results in a stronger and more durable pulp. Chemical pulps are preferred for high-end products like packaging and specialty papers.

-

Other Processes (e.g., Semi-Chemical): There are other niche pulping methods, like semi-chemical processes, which use a combination of mechanical and chemical techniques. These methods are typically used for specific applications where a balance between quality and cost is needed.

By Product

Bleached kraft pulp comes in two primary types based on the type of wood used for production:

-

Bleached Hardwood Kraft Pulp: Derived from hardwood trees like eucalyptus, birch, and aspen, this type of pulp is known for its excellent bleachability and lightness, making it ideal for high-quality tissue papers and fine paper products. Hardwood pulp is typically used in applications where a soft, smooth texture is required.

-

Bleached Softwood Kraft Pulp: Produced from softwood trees like pine, spruce, and fir, softwood pulp has long, strong fibers that make it ideal for applications requiring durability and strength. It is predominantly used in premium packaging, graphic papers, and high-end tissue products.

By Application

The versatility of bleached kraft pulp means it finds use in a wide range of applications across various industries:

-

Packaging Paper: The packaging industry is the largest consumer of bleached kraft pulp, particularly due to the growing demand for sustainable packaging solutions. With increasing awareness around plastic waste, bleached kraft pulp is used for producing kraft paper, corrugated boxes, and other packaging materials that are biodegradable and recyclable.

-

Tissue Paper: Bleached kraft pulp is a crucial raw material in the production of soft, absorbent tissue paper. The demand for high-quality tissue products is rising, particularly in the hygiene and healthcare sectors, as well as in the consumer market.

-

Graphic Paper: Bleached kraft pulp is also used in the production of graphic papers, such as printing and writing papers. While digital media has somewhat reduced the demand for traditional printing paper, this segment remains important, particularly in educational and commercial printing.

-

Newsprint Paper: Despite a decline in the newsprint sector due to the rise of digital media, bleached kraft pulp is still used in this application, primarily in developing regions where print media remains essential.

-

Specialty Papers: Bleached kraft pulp is increasingly being used in the production of specialty papers such as currency notes, medical papers, and other niche applications requiring high-strength and specialized qualities.

Regional Analysis: Where Is the Market Growing?

The demand for bleached kraft pulp varies significantly by region, driven by local industrialization rates, government regulations, and consumer preferences.

-

North America: The North American market is driven by a combination of sustainable practices and robust industrial applications. The U.S. and Canada are major consumers of bleached kraft pulp for packaging, tissue, and specialty papers, with a focus on meeting environmental standards.

-

Europe: Europe, particularly countries like Sweden, Finland, and Germany, is a significant market for bleached kraft pulp due to the region’s strong focus on sustainability and environmental regulations. The European market is increasingly focusing on sustainable paper products in line with the European Union’s green initiatives.

-

Asia-Pacific: Asia-Pacific represents the largest and fastest-growing market for bleached kraft pulp. Countries like China, India, and Japan are seeing strong growth in demand for paper products, particularly in packaging and tissue. As these countries industrialize and urbanize, the demand for paper products continues to rise, boosting the bleached kraft pulp market.

-

Latin America and Africa: The markets in these regions are also growing, driven by increased paper consumption and industrialization. Countries like Brazil and Argentina are expanding their pulp and paper production capabilities to meet local and international demand.

Market Dynamics: Drivers, Challenges, and Opportunities

The bleached kraft pulp market is influenced by several key dynamics:

Key Drivers:

- Sustainability Trends: Increasing demand for sustainable packaging materials and eco-friendly paper products is a significant driver for the bleached kraft pulp market.

- Rising Paper Consumption: With growing economies, particularly in Asia-Pacific, the need for paper products is expanding rapidly, driving demand for bleached kraft pulp.

- Technological Innovations: Advances in pulping and bleaching processes are making production more efficient, cost-effective, and environmentally friendly, further bolstering the appeal of bleached kraft pulp.

Challenges:

- Environmental Concerns: While kraft pulp is relatively sustainable, the deforestation required for wood pulp production remains a challenge. Sustainable sourcing practices and certifications are becoming essential to ensure compliance with environmental regulations.

- Price Fluctuations: The price of raw materials, particularly wood, can fluctuate, affecting the cost structure of pulp production.

Opportunities:

- Sustainable Packaging Growth: The shift towards biodegradable and recyclable packaging presents significant growth opportunities for bleached kraft pulp, particularly in e-commerce and consumer goods packaging.

- Emerging Markets: As developing regions continue to industrialize and urbanize, demand for paper products will drive increased consumption of bleached kraft pulp, offering new growth avenues.

Competitive Landscape: Key Players and Market Share

The global bleached kraft pulp market is highly competitive, with several key players leading the industry:

- International Paper Company

- UPM-Kymmene

- Sappi Limited

- Stora Enso

- Asia Pulp & Paper Group

These companies dominate the market with large-scale production capabilities, a global presence, and innovations in sustainable pulp production. They continue to focus on reducing environmental impact and improving the quality of their products to meet the growing demand for eco-friendly solutions.