When it comes to HVAC systems in both residential and commercial buildings, coils play an essential role in regulating temperature and humidity. These components help to transfer heat, keeping spaces comfortable throughout the year. However, coil failures are a common and costly issue, often causing reduced efficiency, higher energy bills, and the need for frequent maintenance or replacement. In this article, we’ll dive into the primary reasons for coil failures, providing building owners and maintenance professionals with insights on how to prevent these issues and prolong the life of HVAC systems – https://acjakarta.com.

1. Corrosion: A Leading Cause of Coil Failure

Corrosion is one of the top reasons for coil failure in HVAC systems. Coils, typically made of copper or aluminum, are vulnerable to corrosion due to prolonged exposure to moisture, pollutants, and other environmental factors. There are two main types of corrosion that impact coils:

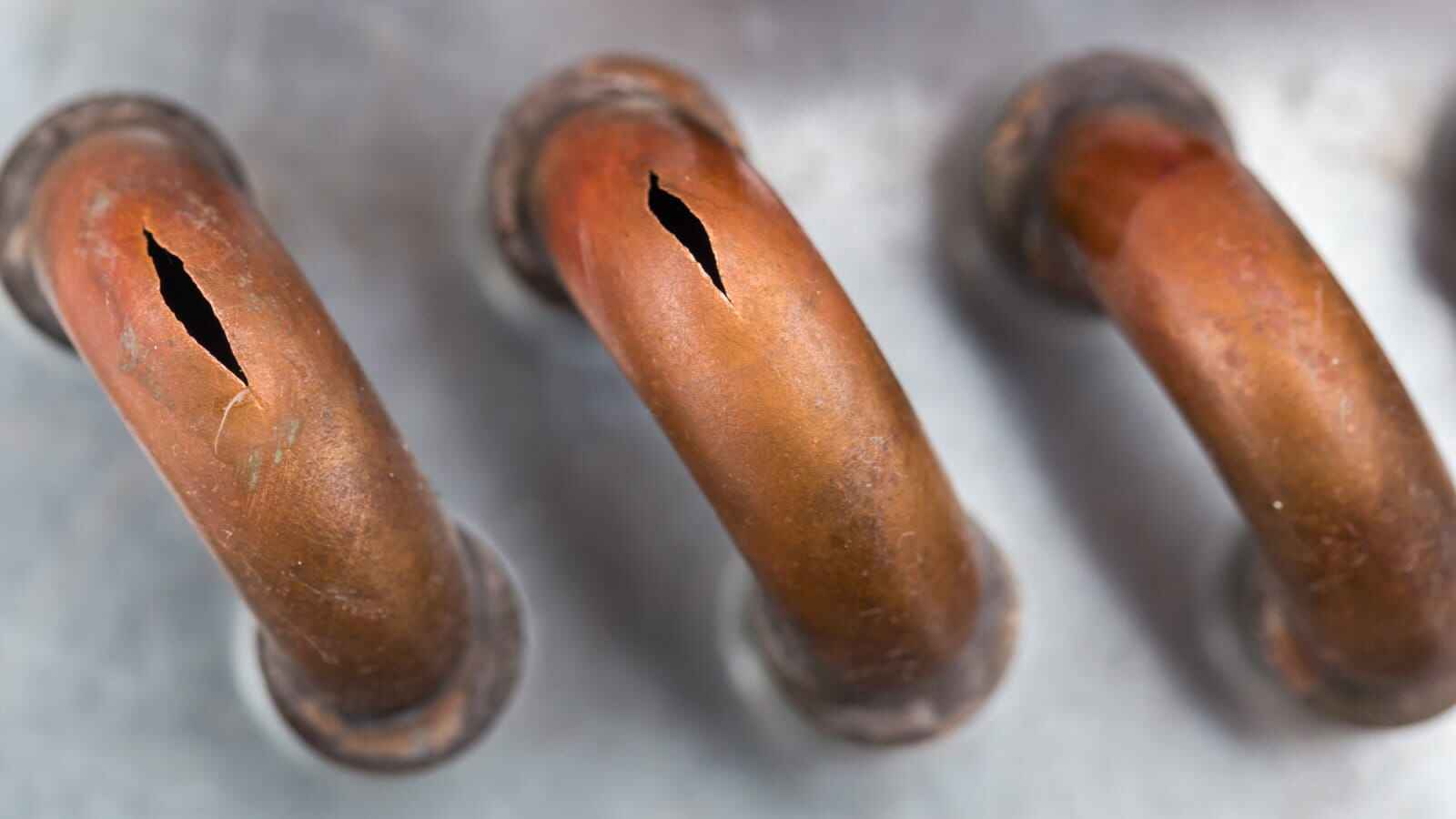

Formicary Corrosion: Also known as “ant-nest corrosion,” this type often affects copper coils. It is caused by organic acids from sources such as cleaning agents, insulation materials, or household products that degrade and release corrosive agents. Formicary corrosion creates tiny holes that can lead to refrigerant leaks and decreased performance.

Pitting Corrosion: Commonly found in aluminum coils, pitting corrosion occurs due to chemical reactions between the metal and environmental contaminants. This type of corrosion also leads to leaks, causing coil failure if left untreated.

Prevention Tips

Install protective coatings on coils to prevent corrosion.

Regularly clean coils to remove dust, dirt, and other contaminants.

Consider using closed-cell insulation to reduce chemical exposure.

2. Dirty Coils: Reduced Efficiency and Increased Wear

Over time, dirt, dust, and debris accumulate on the coils, creating a layer that insulates the coil from airflow. Dirty coils reduce the HVAC system’s efficiency, forcing it to work harder to cool or heat a space. This additional strain not only increases energy usage but also accelerates coil wear and can lead to premature failure.

Prevention Tips

Schedule regular HVAC maintenance to clean coils and check for dirt buildup.

Install high-quality air filters to reduce the amount of dirt reaching the coils.

Encourage routine inspections, especially in high-traffic areas, to detect and address dirt buildup early.

3. Improper Installation and Maintenance Practices

Coils are sensitive to the correct installation and routine maintenance. Improper handling during installation can damage the coils or place unnecessary strain on them, shortening their lifespan. Poor maintenance practices, such as using incorrect cleaning agents or neglecting coil inspections, can also lead to coil failure.

Prevention Tips

Ensure HVAC technicians are certified and trained in best practices for installation and maintenance.

Use manufacturer-recommended cleaning products to avoid damage.

Schedule regular maintenance checks to catch potential issues early.

4. Refrigerant Leaks: Cooling Efficiency Plummets

Refrigerant leaks are a significant factor in coil failure. When coils begin to leak refrigerant, the system loses its cooling capacity, putting additional strain on the compressor. Over time, the lack of sufficient refrigerant can cause the compressor to overheat and fail, which is both costly and preventable.

Prevention Tips

Regularly inspect coils and connections for signs of leaks.

Use leak detection tools to identify issues before they become severe.

Monitor refrigerant levels and address discrepancies promptly.

5. Thermal Stress: Expansion and Contraction Cycles

As HVAC systems run, the coils repeatedly expand and contract in response to temperature changes. Over time, these thermal stresses cause the coils to weaken and may result in cracks or other forms of physical damage. This is especially common in systems that frequently cycle on and off or operate under extreme temperature fluctuations.

Prevention Tips

Consider installing variable-speed systems that reduce the number of on-off cycles.

Regularly inspect coils for signs of physical stress or damage.

For high-stress environments, choose coils made from materials that withstand repeated thermal expansion.

6. Environmental Factors: Salt, Pollutants, and Moisture Exposure

Buildings located in coastal areas or highly polluted environments face additional risks for coil failure. Salt air and industrial pollutants accelerate the corrosion process, and in humid climates, excess moisture can contribute to mold and mildew growth on the coils. This not only affects coil integrity but also reduces indoor air quality.

Prevention Tips

For coastal or industrial areas, use coated or specially treated coils that resist corrosion.

Install dehumidifiers in particularly humid environments to reduce moisture levels.

Increase the frequency of coil inspections and cleanings for buildings in harsh environments.

Final Thoughts: Protecting HVAC Coils and Enhancing System Longevity

Coil failures are a common challenge in HVAC systems, but with proper preventative measures, building managers and homeowners can reduce the risk and prolong the life of these essential components. Regular maintenance, proactive inspections, and the use of protective coatings are all strategies that can significantly reduce corrosion, prevent leaks, and keep the system running efficiently.

For buildings facing persistent coil issues, it may be worthwhile to consult with HVAC professionals who can recommend upgrades or specialized treatments to address specific environmental challenges. By taking a proactive approach, building owners can avoid the high costs of coil failures and maintain comfortable indoor environments year-round.

By understanding and addressing these common causes of coil failures, homeowners and building managers can improve HVAC performance, reduce costly breakdowns, and ensure a more energy-efficient system that stands the test of time.