Understanding Pressure Vessels

A pressure vessel is a container designed to hold gases or liquids at a pressure different from the ambient pressure. Pressure vessels play a critical role across various industries, including petrochemical, oil and gas, and food processing. They store potentially hazardous substances under high pressure, making them essential for safe and efficient industrial operations.

Types of Pressure Vessels

Pressure vessels come in various shapes and sizes, each designed for specific purposes. The three main types include:

- Storage Tanks: Primarily used to store gases and liquids, such as fuel and water, at different pressure levels.

- Boilers: Typically used in power plants and other facilities to heat water or other fluids to generate steam.

- Process Vessels: Found in refineries and manufacturing plants to store, mix, or separate chemical substances under pressure.

How Pressure Vessels Work

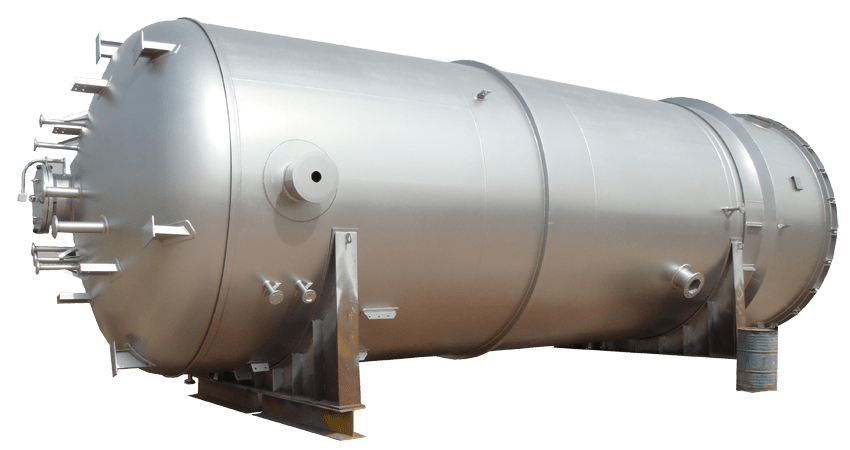

The design of a pressure vessel includes robust materials and specific configurations to handle varying levels of pressure. Pressure vessels generally have three key components:

- The Shell: This is the main body and can be spherical or cylindrical, depending on the application.

- The Heads: These are end closures and often come in various shapes, such as flat, elliptical, or spherical.

- The Nozzles and Openings: These provide access points for inserting and extracting the content, as well as for monitoring the vessel’s pressure and temperature.

The pressure within the vessel is carefully monitored and controlled. When the gas or liquid reaches the desired pressure level, safety valves release the excess to prevent damage or accidents.

Importance of Material Selection

Selecting the right material is critical for the safety and performance of a pressure vessel. Often made from carbon steel, stainless steel, or alloy materials, pressure vessels must endure high pressure, corrosive chemicals, and extreme temperatures. Different applications require materials with specific properties to withstand environmental conditions and prevent leaks or explosions.

Fact About Pressure Vessels

Did you know? Most pressure vessels are designed with a safety factor of around 3.5. This means they can handle 3.5 times more pressure than their operational limit, ensuring safety and durability.

Key Design Standards and Regulations

Strict regulations govern the design and maintenance of pressure vessels to ensure safety. In the United States, the American Society of Mechanical Engineers (ASME) provides codes and standards for designing and constructing pressure vessels. The ASME BPVC (Boiler and Pressure Vessel Code) outlines detailed specifications that every pressure vessel must meet to be certified for industrial use.

Safety Measures and Testing for Pressure Vessels

Because pressure vessels contain high-pressure materials, they require rigorous safety measures and frequent testing. Some key safety protocols include:

- Hydrostatic Testing: The vessel is filled with water and pressurized to detect any leaks.

- Ultrasonic Testing: This technique examines the vessel’s walls for flaws or weaknesses.

- X-ray Inspection: Used to inspect welds and ensure they are free from cracks.

Ensuring regular maintenance and inspections is essential for the vessel’s longevity and operational safety.

Choosing the Right Pressure Vessel

When selecting a pressure vessel, it’s vital to consider factors such as the intended application, operating pressure, temperature, and the chemical properties of the stored substance. Many pressure vessel suppliers offer customized solutions to meet these specific needs, providing industries with equipment tailored to their operational requirements.

Conclusion

Understanding what a pressure vessel is and how it works is fundamental to maintaining industrial safety and efficiency. These structures enable the storage and handling of high-pressure materials while adhering to stringent safety standards. Selecting a suitable pressure vessel that meets regulatory and operational requirements ensures optimal performance and safety across industries.

Buraq Engineering is a global leader in manufacturing top-quality pressure vessels, delivering innovative solutions to industries worldwide. With a commitment to safety, precision, and reliability, Buraq Engineering designs and supplies high-performance pressure vessels tailored to meet the diverse needs of sectors such as oil and gas, chemical processing, and power generation. Each vessel adheres to strict international standards, ensuring durability and efficiency even in the most demanding environments. Trusted by clients globally, Buraq Engineering continues to set the benchmark in pressure vessel manufacturing.